AMEST inspection and measuring stations provide comprehensive inter-operational and final inspection of components, sub-assemblies and final products. They check dimensions, shapes, prescribed weight, quality of machining and compliance with the quality requirements of the material used. They can be equipped with automatic feeding of inspected parts, special dimensional sensors and probes for eddy current inspection, scales, markers and automatic sorting of inspected parts according to selected parameters.

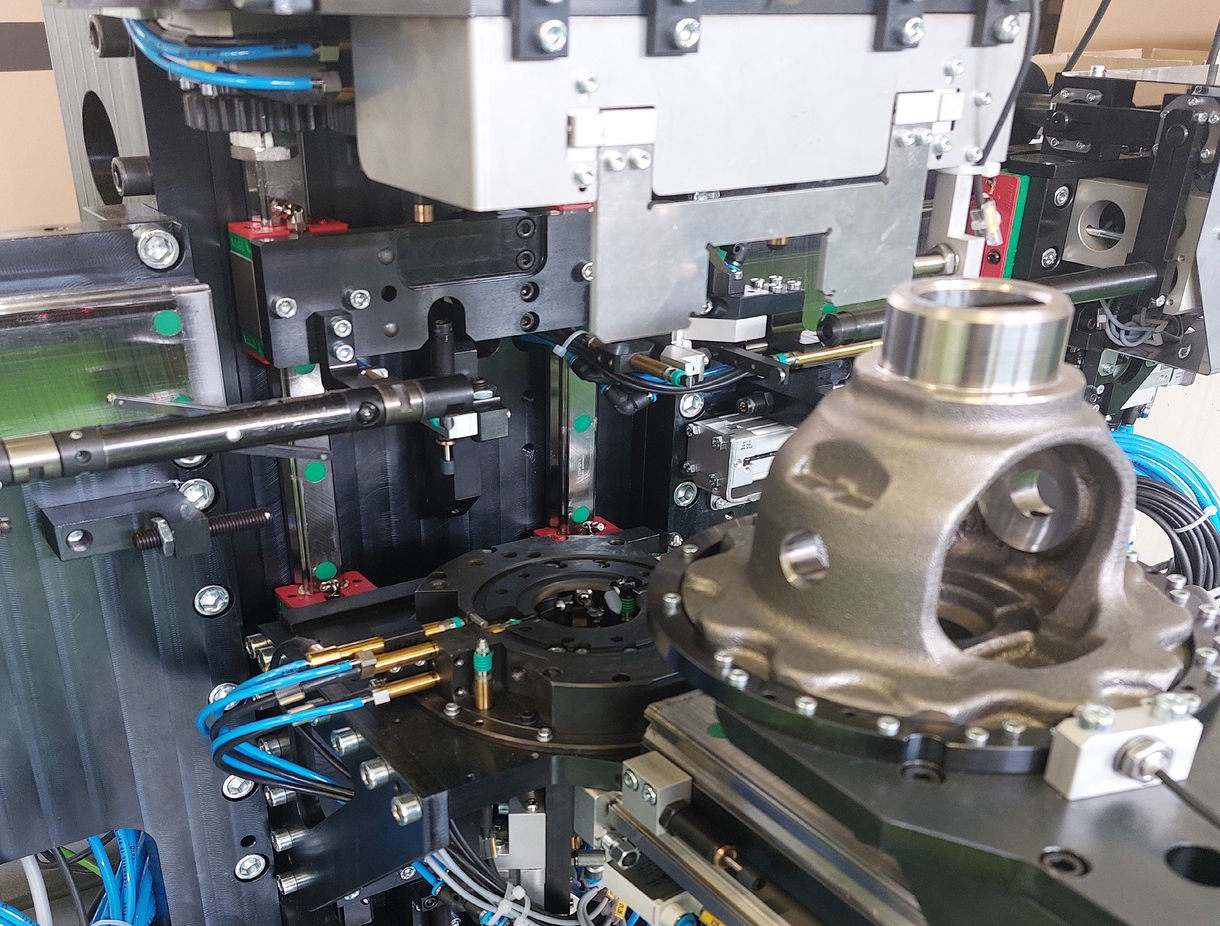

Automatic measuring station for dimensional control of differential housings

Zjistit více

Precision cylindrical surfaces

The measuring station designed for diameter, straightness and cylindricity jet bore measurement consists of a rigid foundation plate.

Zjistit více

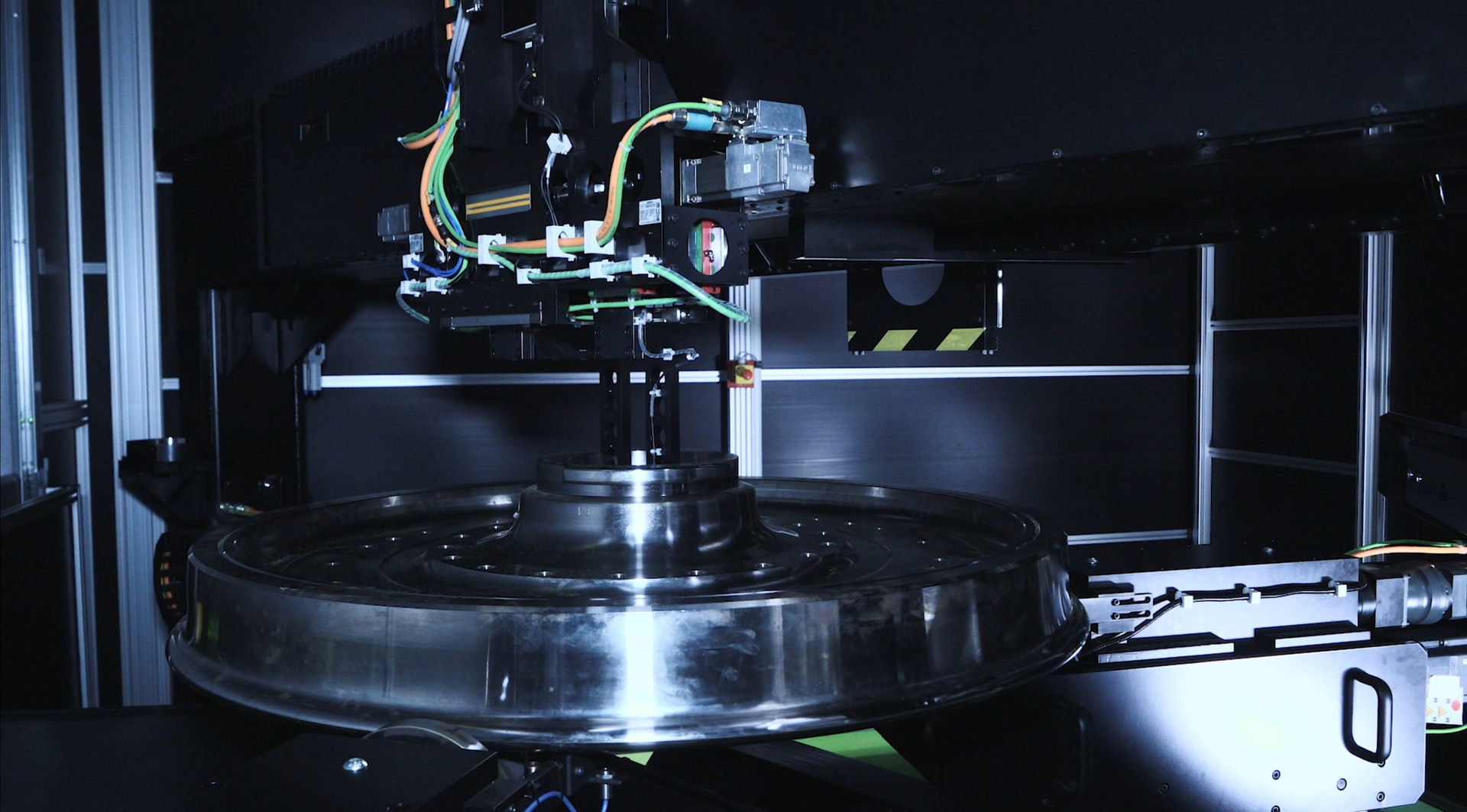

The automatic measuring stations for the measurement of shafts and flanges after various technological operations.

Zjistit více

The automatic measuring station KS-517 performs the clearance dimension measurement in the piston rings gap when constricted to its relevant nominal diameter.

Zjistit více