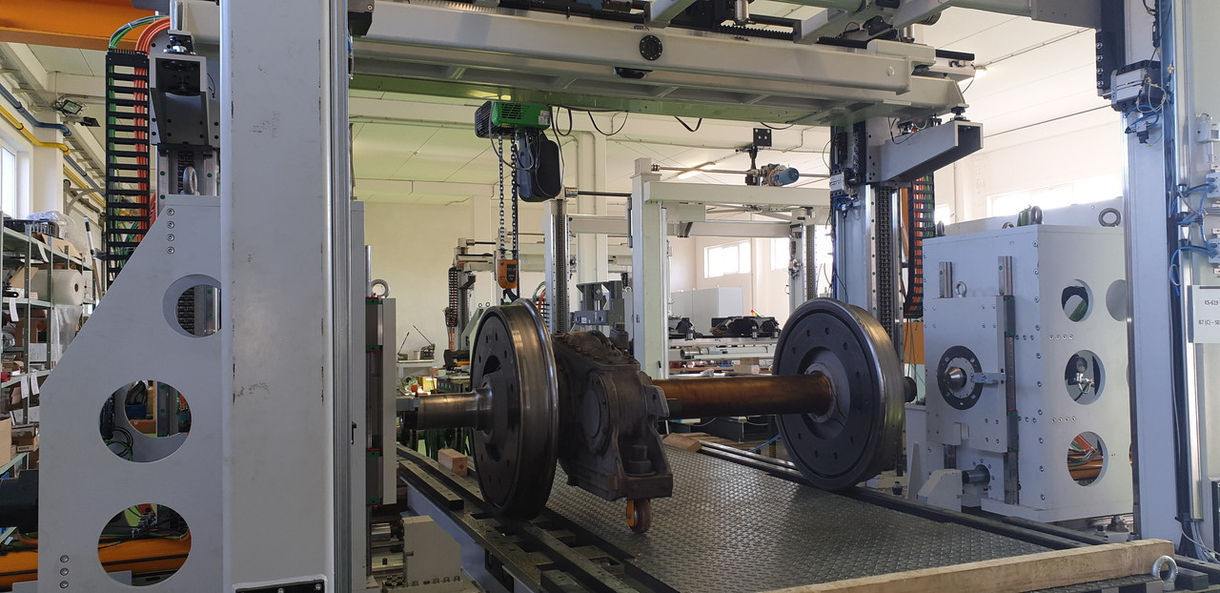

AMEST inspection and measuring stations provide comprehensive inter-operational and final inspection of components or assembly

ProductsAutomotive and rail industry

Automatic measuring stations

For production control of dimensions and shapes of components.

Our clients

About us

More than 600 installations of our technology

During our time in the field of precision measurement and production control, we have carried out more than 600 installations of our technology in leading domestic and foreign companies, including the largest engineering company in the Czech Republic - ŠKODA AUTO Mladá Boleslav.

In doing so, we have gained a lot of valuable experience, both in the field of measurement and production control and in the cutting-edge technology of engineering production.

- 26+ employees

- in 34 countries

- 2 exhibitions per year

What we measure

We measure length dimensions, shape and position deviations, general shapes, surface roughness.

How we measure

We use modern measuring methods - camera, laser, touch methods and others.

Where we measure

We measure in a normal workshop environment, at specialised workplaces.