Automatic measuring station for measuring of railway wheels geometric dimensions

The automatic measuring complex developed by company Amest is designed to measure complete geometry of railway wheels

Zjistit více

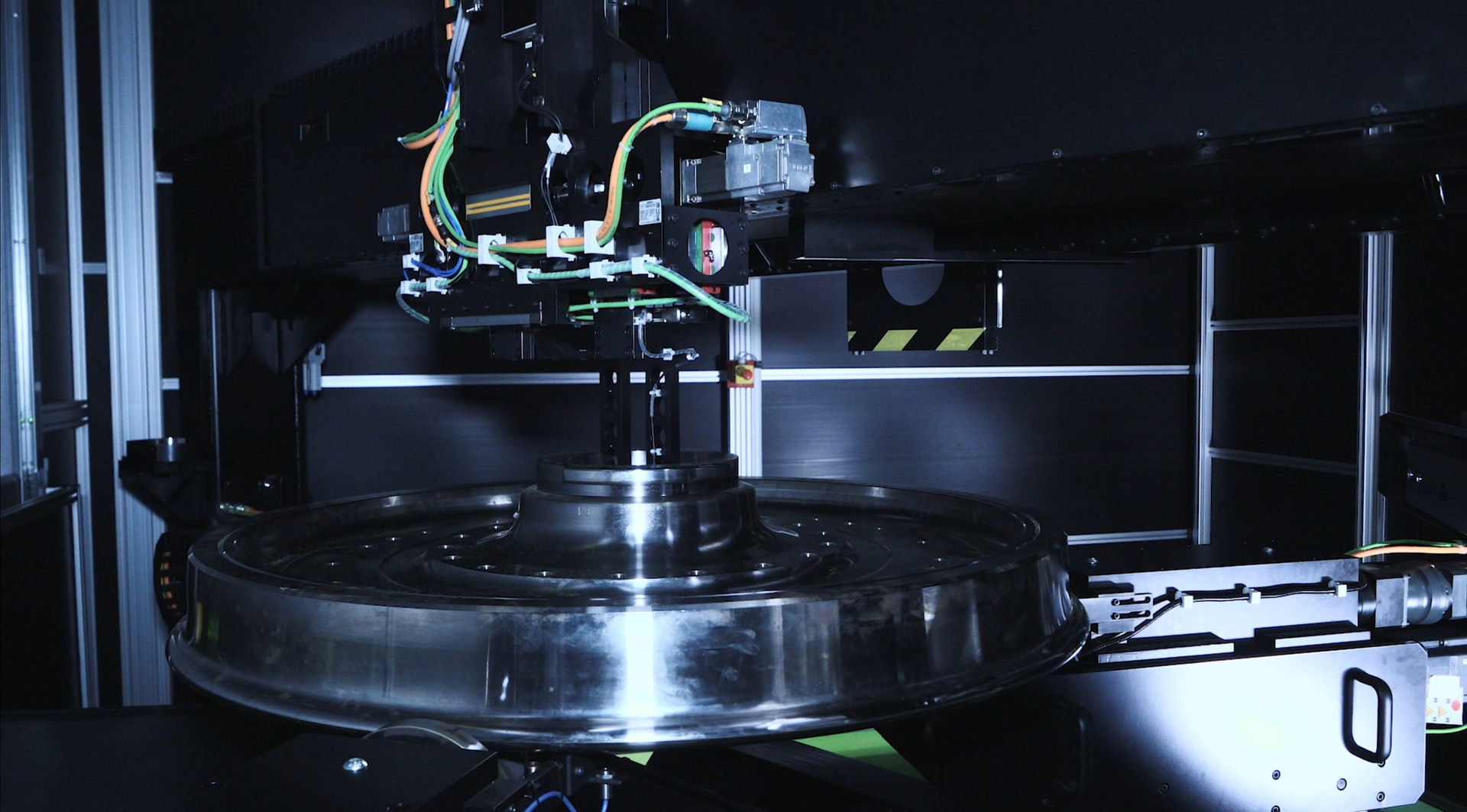

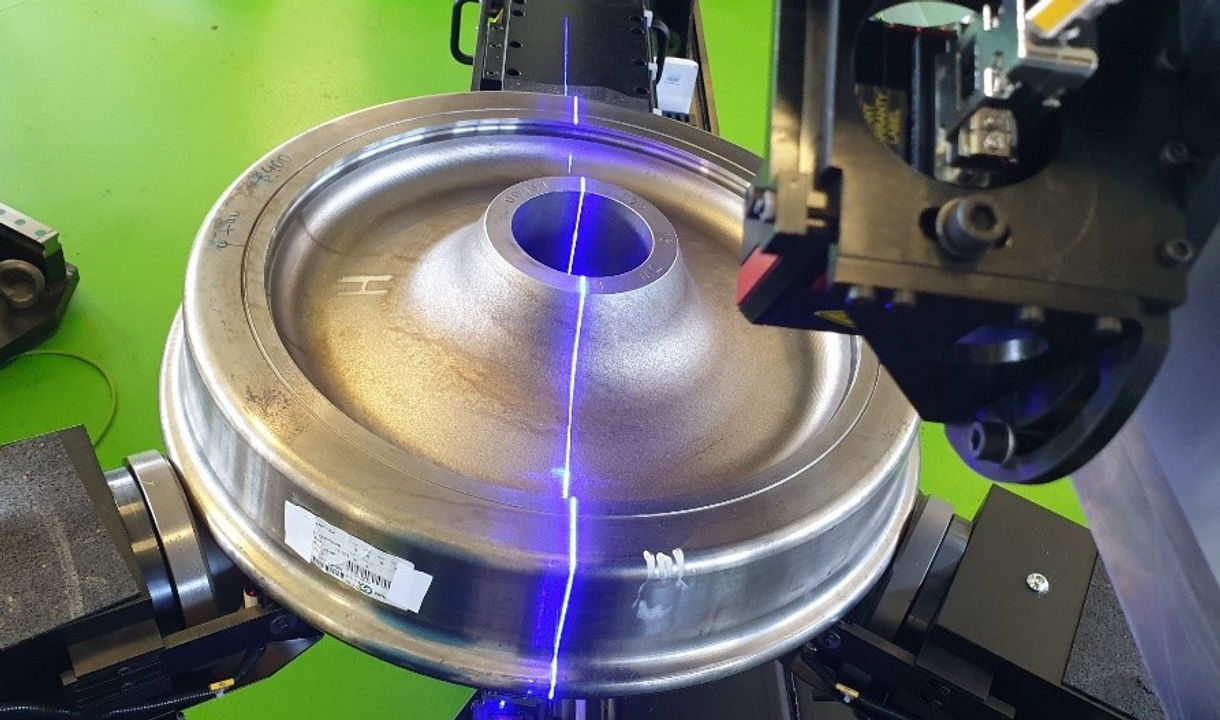

The automatic measuring complex developed by Amest is used to make a complete check on wheels manufactured in non-stop three-shift serial production. The station is easy to set for all types and dimensions of wheels manufactured in the client’s factory, i.e. from small tram wheels to huge locomotive wheels. To ensure reliability of optical components the entire station is situated in a lockable compartment with opaque sliding walls and an inner roller-blind to keep it sheltered and protected against light. The output of the station – checking 60 wheels an hour, including assessment and statistical processing of the results – can match the tempo of the client’s production line by a sufficient margin.

Automatic measuring station for measuring of railway wheels geometric dimensions

The automatic measuring complex developed by company Amest is designed to measure complete geometry of railway wheels

Zjistit více

Automatic measuring station for measuring of wheel-sets geometric dimensions

The automatic measuring station developed by company Amest is designed to measure complete geometry of railway wheel-sets

Zjistit více

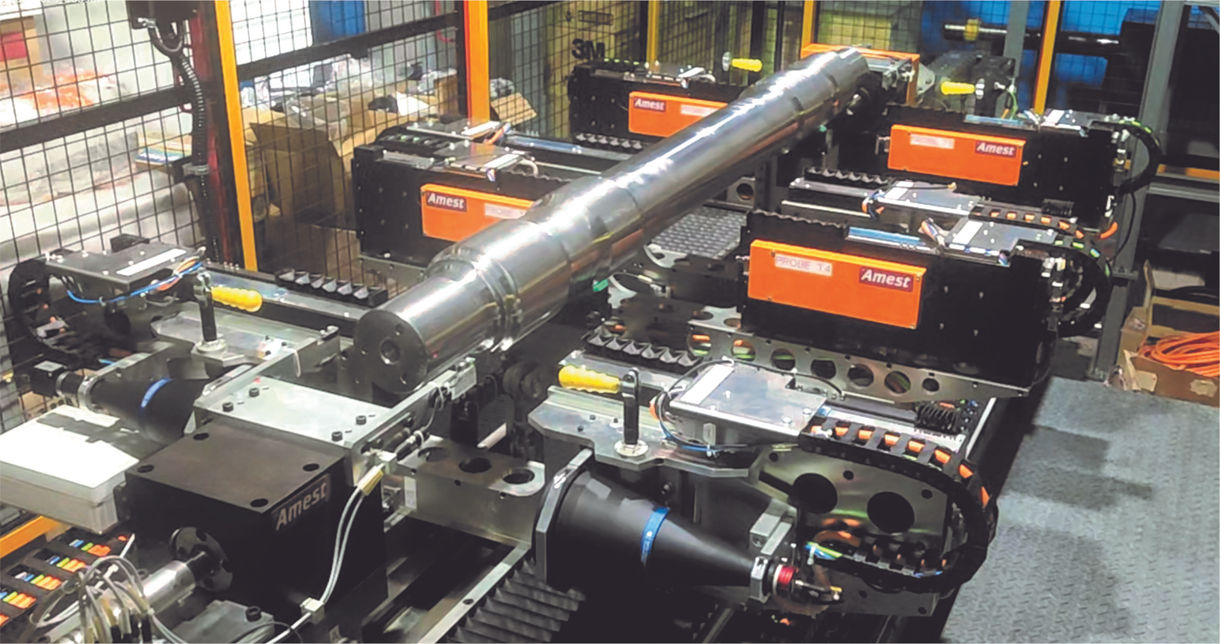

Visual, dimensional and geometric checking device for measurement of forged railway axles

Automatic measuring station for visual, dimmensional and geometry measurement of railway axles after forging

Zjistit více

Automatic measuring station for geometry control of final railway axles

Geometry control of final railway axles in serial production

Zjistit více

NDT testing of railway wheels and axles

Ultrasound and magnetic testing of railway wheels and axles

Zjistit více