AMEST inspection and measuring stations provide comprehensive inter-operational and final inspection of components or assembly

ProductsOur products

Products for the automotive and railway industry

We provide industrial companies with qualified consulting services to solve specific problems of precision measurement, production control and optimal production technology.

AMEST tracking gauges are designed for checking the dimensions and shapes of workpieces and controlling the work cycle on cylindrical and cylindrical grinding machines.

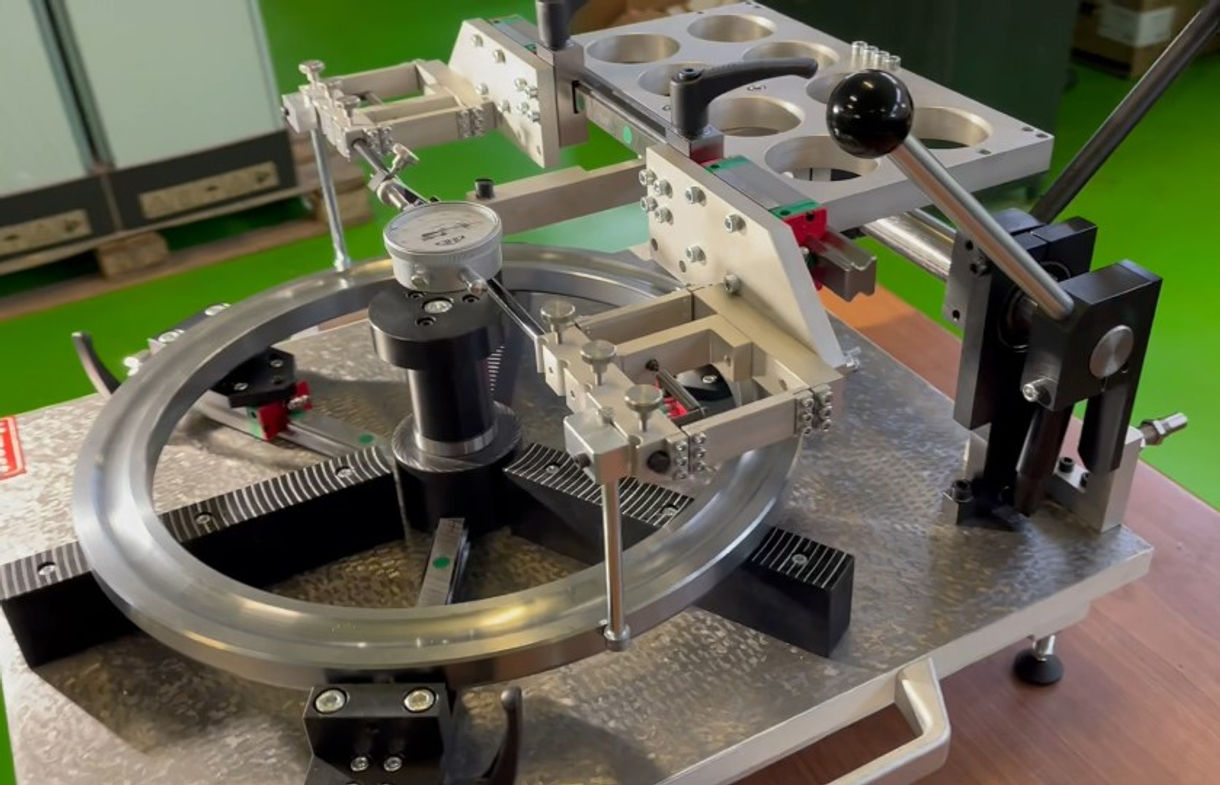

ProductsThe automatic measuring complex developed by Amest is used to make a complete check on wheels manufactured in non-stop three-shift serial production.

ProductsAMEST inspection fixtures are single-purpose devices without evaluation electronics that enable inexpensive, fast and simple inspection of manufactured components with minimal operator requirements.

Products